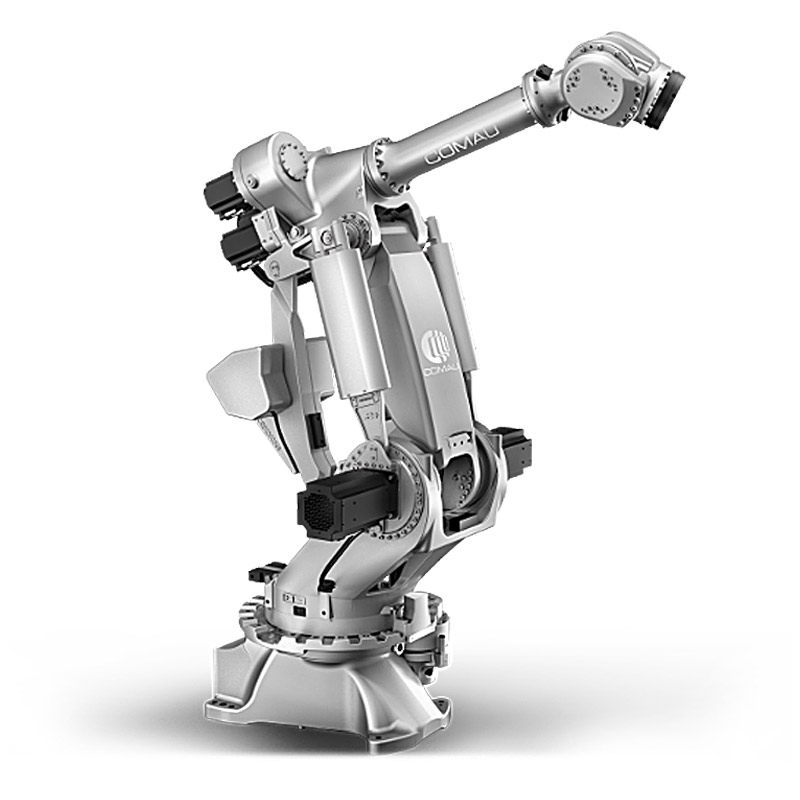

Robots of NJ series have 6 axles which makes it possible to operate in full 3D space – i.e. to receive elements from sloped feeders, place single elements on the pallet in a precise and gentle manner. It allows greater mobility of the robot in a working area as well as easier trajectory programming in the production space.

The family of robots of NJ series with a lightweight construction was designed to reduce the weight and overall size of the robots, achieve better performance as well as shorten the cycle time and reduce the energy consumption (up to 25% less than in similar models). Moreover, it meets the requirements concerning the environmental compatibility and safety. Models NJ 110-130-165-220 are widely applied in processes of palletizing. The fourth and fifth robot axles perform an important role – thanks to them non-perpendicular products or goods might be transferred, if it is required by the process. Those robots are very flexible as far as the configuration options of the robotic cell are concerned: they might be installed on a pedestal, ceiling or in an inclined position.