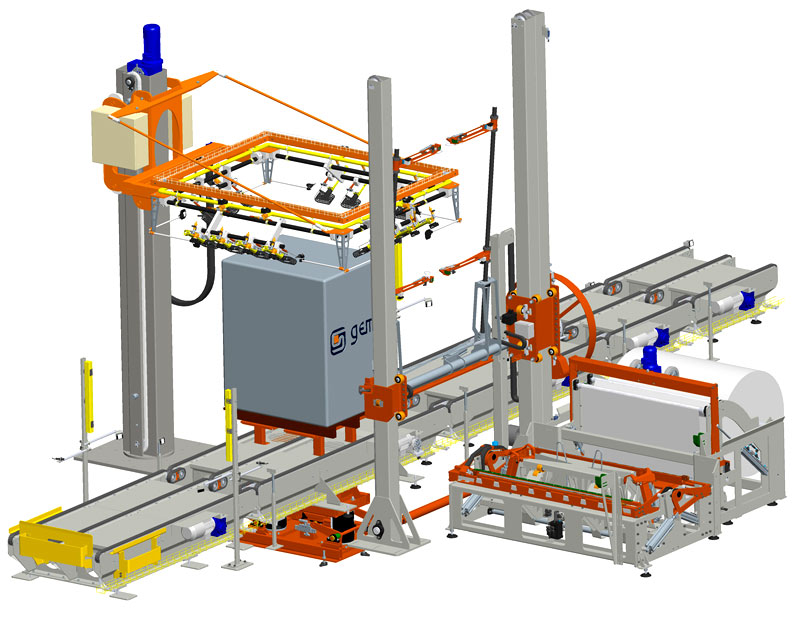

GLS-FR automatic frame type shrinking machine with a hood putting unit for packing the pallet loads into the hoods made of thermo-shrinking hoods, with output capacity 60 pack./h. The load is immovable during the shrinking operation.

GLS-FR is individually designed according to the investor demands and integrated with the existing units of packing line. The lifters before and after the shrinking machine are adapted to existing lines conveyor route lines.

Example