LOGIPAK trade fair.

This time we decided to take part in LOGIPAK trade fair organized simultaneously with Taropak trade fair. Together with you – our customers, we will celebrate our first quarter of a century of our company. We would like to thank you for their cooperation and ask for new challenges – as because of them we are developing and striving for increasing the level of the services offered.

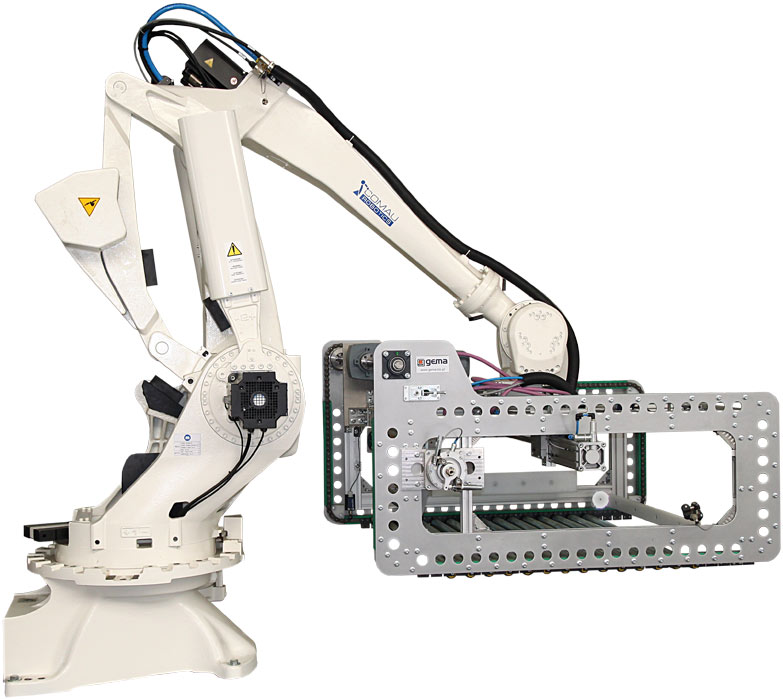

A ring wrapping machine with additional features

A ring wrapping machine with the following additional features was implemented to production: a system of “lacing” the film which replaces striping with a tape, and a lift with two rolls of stretch film – the second roll is printed (e.g. with a company logo) and might serve as a carrier of information and advertisements.

Certificate of Payment Credibility – „Złoty Płatnik 2015” `{`Golden Payer 2015`}`.

Although the most valuable prizes for us are next orders from you – our clients, we are pleased to inform that the financial credibility of Gema deserves the highest ratings according to Creditreform and Eurel Hermes – those institutions granted us the Certificate of Payment Credibility and title of „Złoty Płatnik 2015”.

„Gazele Biznesu” `{`Business Gazelles`}`

The 25. year of our operation started quite unexpectedly. We were awarded the prize (although as a rule we do not participate in any competitions) and we became the “Business Gazelle”. This title is awarded for fulfilling a few objective criteria: revenue growth, increase in profits, and transparency of business.

The line with a horizontal wrapping machine

The line with a horizontal wrapping machine for packing long elements with a stretch film, and with an automatic feeder of flanges replacing the pallet. The following might be programmed: places to be wrapped, a number of wrappers, automatic wrapping and cutting off the film, and sticking film edges to the pallet automatically.

A ring wrapping machine with the system to place corner beads

It is a new option which is important in those places where the product is exposed to damages and cargo edges must be additionally protected. The corner beads are distributed automatically from four containers, placed on the cargo edges, held in a proper position in order to continue wrapping at full capacity.

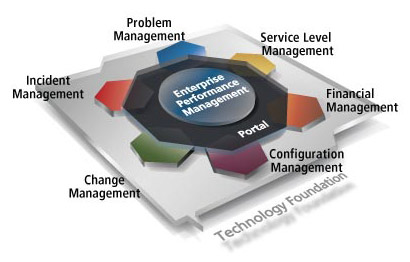

EPICOR

EPICOR – Next-Generation ERP Applications.

We finished introducing Epicor’s company program. Epicor company has been classified as a ‘visionary’ by Gartner independent agency.

Epicor’s applications have been used by over 33 000 customers in over 150 different countries. GEMA has been included in that number as one of the first companies in Poland.