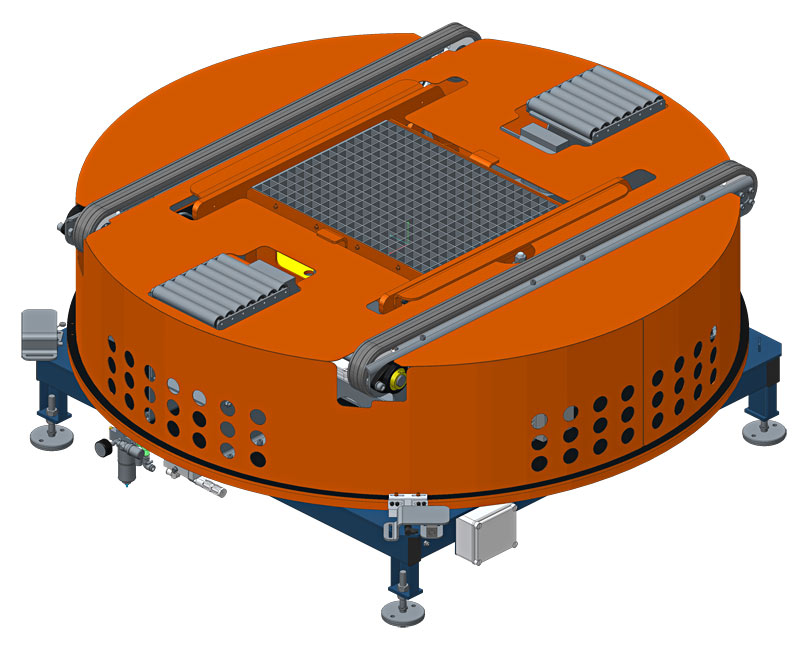

Turning roller-chain conveyors are used to change the direction of the pallet movement and to change the side. In the solution presented below, the cargo is moved along the chain conveyor via stringers across the conveyor. After delivering onto the turntable, the rollers are lifted and the loaded pallet, already placed on the rollers, is rotated and goes down from a different side onto the roller conveyors.

Turning roller-chain conveyors – example

| diameter | 1800 mm |

| operating width | 1000 mm |

| height | 800±30 mm |

| angle of rotation | 0 do 90o |

| chains | 3 szt. |

| stroke of the lift | ~ 50 mm |

| speed | regulated (frequency converter) |

| load | 1500 kg/m |

| range of temperatures | 0÷40°C |

| construction | steel construction powder painted, surface chemically prepared |

| installation | floor, with steel anchors |

Turning roller-chain conveyor with a fan

Turning roller-chain conveyors with a fan are used to package the cargos properly with thermos-shrinkable hoods.

After entering the chain conveyor of the turntable, the loaded pallet, covered with a film hood, is lifted with a pneumatic lift up to the height of approximately 150 mm, the fan is turned on which sucks out the air under the hood and then, the process of shrinking might be initiated which guarantees good quality of the packaging.

Turning roller-chain conveyor with a fan – example

| diameter | 1800 mm |

| working width | 1000 mm |

| height | 800±30 mm |

| angle of rotation | any, in both directions |

| chains | 2 |

| stroke of the lift | ~ 150 mm |

| speed | regulated (frequency converter) |

| load | 1500 kg/m |

| range of temperatures | 0÷40°C |

| construction | steel construction powder painted, surface chemically prepared |

| installation | floor, with steel anchors |

Photos